MEGA-T400A 16-inch Automated Metallographic Abrasive Cutter

The MEGA-T400A 16-inch automated metallographic abrasive cutter is a high-performance solution designed to deliver precise, safe, and repeatable cuts across a wide range of materials. This system combines automated and manual operation, providing the flexibility to suit various cutting needs and operator skill levels.

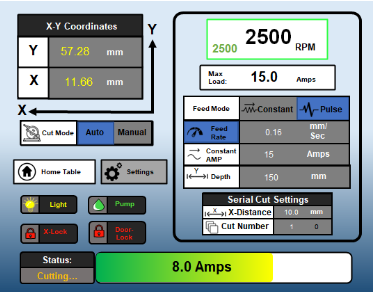

It features automatic or manual Y-axis feed (with optional automatic X-axis feed), offering enhanced control over the cutting path. The high-torque servo motor and variable speed cutting system ensure powerful, efficient, and consistent performance—even under demanding conditions.

With both wheel and table feed mechanisms, and the ability to choose between constant feed or constant cutting force control, the MEGA-T400A adapts easily to different materials and hardness levels. The T-slot table provides stable, secure sample fixturing, while the intuitive touch screen interface simplifies operation and setup.

Robust, precise, and easy to use, this cutter is ideal for metallographic laboratories, industrial workshops, and research centers in need of a reliable, highly automated system for high-quality sectioning.

Description

| Specification | Description |

|---|---|

| Cutting Type | Automated / Manual cutting |

| Y-axis Feed (X-axis optional) | Auto / Manual Y-axis feed (optional Auto X-axis feed) |

| Motor | High torque servo motor |

| Cutting Speed | Variable speed cutting |

| Feed Mechanism | Wheel and table feed cutting |

| Feed Mode | Constant feed or constant cutting force control |

| Table Fixturing | T-slot table fixturing |

| Control Interface | Touch screen control |